MEP Design

Smart, coordinated building systems designed for comfort, performance, and maintainability.

Chenla’s MEP design team integrates mechanical, electrical, and plumbing systems into efficient, code-compliant solutions — fully coordinated with architecture and structure from day one.

Our MEP Design Services

💨 Mechanical Systems

- HVAC design for comfort and energy efficiency

- Load calculations, duct sizing, and equipment selection

- Ventilation, smoke control, and fire systems design

- Thermal performance modeling and optimization

⚡ Electrical Systems

- Power distribution and panel schedules

- Lighting design and control layouts

- Emergency, earthing, and lightning protection systems

- Low-voltage systems (CCTV, access control, data)

🚰 Plumbing & Drainage

- Cold and hot water distribution systems

- Drainage and vent pipe routing and sizing

- Rainwater harvesting and water reuse systems

- Coordination with civil and structural elements

🧠 Integrated Coordination

- 3D MEP modeling in Revit with clash detection

- Integration with structural and architectural models

- Load summaries, equipment schedules, and IFC documentation

- Design reviews for maintainability and accessibility

Why MEP Design Matters

MEP design is where building performance truly takes shape. Our integrated engineering approach ensures systems work together seamlessly — providing comfort, safety, and efficiency throughout your building’s lifecycle.

Early Coordination Reduces Cost

Clashes between ducts, pipes, and structure are resolved digitally before they reach the site — saving time and money.

Energy Efficiency by Design

Optimized systems lower operating costs while improving occupant comfort and environmental performance.

Safety & Compliance

Fire systems, emergency lighting, and ventilation are designed in compliance with international codes and local standards.

Lifecycle Thinking

Designs consider long-term operation and maintenance — ensuring reliability throughout the building’s life.

Cross-Discipline Integration

Electrical, mechanical, and plumbing teams coordinate closely to prevent conflicts and deliver unified outputs.

Global Standards, Local Adaptation

Design outputs follow ASHRAE, IEC, and IPC standards while adapting to Cambodian construction practices.

Selected Case Study

This infrastructure strategy protects mission-critical operations, prevents contamination risk, and sustains 24/7 continuity even under flood and utility failure scenarios.

Case Study

Resilient Infrastructure & Smart Research Backbone

Engineering 24/7 continuity for a national research facility

Executive Summary

Chenla Agathos designed an integrated civil, sanitary, HVAC, and digital resilience strategy for the DOA Future Lab and HPC Center. The solution defends against flooding, prevents laboratory contamination risk, and guarantees mission-critical uptime through redundancy and commissioning-grade validation.

Project Snapshot

- Client

- Department of Agricultural Affairs (DOA)

- Location

- Chatuchak (Bang Khen), Bangkok, Thailand

- Site Area

- Approx. 25,000 sqm GFA

- Contract Value

- USD 3 million

- Duration

- 36 months (design & construction)

- Services Delivered

- Civil Engineering, Sanitary & Chemical, Laboratory HVAC & Special Ventilation, Waste Management, Hydraulic Modeling, HPC Infrastructure (Cooling & Power), Digital Commissioning

The Challenge

The context, constraints, and risks shaping the project from the start.

For a national research facility, infrastructure failure is not an inconvenience; it is mission loss. The DOA Future Lab demanded a zero-tolerance approach to flood risk, contamination control, and digital uptime to protect research samples, equipment, and data.

Complexity

- Flood vulnerability requiring defense against catastrophic operational loss

- Strict contamination and discharge requirements for laboratory chemical waste

- Mission-critical HPC uptime requiring redundancy beyond conventional approaches

What Was at Stake

Without resilient civil and MEP systems, a single flood event or utility failure could disrupt operations, compromise safety and compliance, and cause severe financial and research losses.

How Chenla Stepped In

The targeted actions we took to resolve the core issues.

Chenla delivered an integrated resilience design combining flood-defense civil works, secure water and waste systems, laboratory-grade HVAC containment, and redundant HPC power/cooling validated through commissioning-level testing.

Key Actions

- Set an elevated platform target of +1.5 m based on hydraulic modeling and drainage limits

- Designed a 50,000 L water reserve for minimum 48-hour continuity

- Implemented a gravity-based Down Feed Water system to reduce booster dependency and maintain pressure under outages

- Engineered a dual-drain chemical waste network routed to a dedicated pre-treatment plant

- Delivered 100% outdoor air (FAHU-based) lab HVAC with negative pressure zoning and N+1 redundancy

- Designed N+1 dual-path UPS/generator power and dedicated HPC cooling for 50 kW/rack capacity

- Executed digital commissioning through server load testing and failover simulation

Solution Highlights

What Chenla delivered to address the project's challenges.

Flood Defense by Design

A +1.5 m elevated platform protects critical MEP and laboratory systems above historical maximum flood levels.

Water Security & Energy Savings

A 50,000 L reserve and gravity down-feed distribution reduce outage exposure and booster pump energy use.

Laboratory HVAC Containment

100% outdoor air, negative pressure zoning, and dedicated exhaust prevent cross-contamination.

HPC Uptime & Commissioning

Redundant power and high-density cooling were validated through load testing and failover simulation.

Outcomes

What changed for the client as a direct result of our intervention.

Operational Results

- 99.99% guaranteed operational uptime through redundancy and elevation

- 99% reduction in flood risk probability

- 30% reduction in booster pump energy consumption

- Chemical waste treatment capacity of up to 250 L/day

Client Benefits

- Continuity of national research operations during floods and outages

- Reduced contamination risk and stronger regulatory compliance

- Lower long-term energy costs through smarter water distribution

- A secure, validated digital backbone for high-performance research computing

PROJECT DOCUMENTATION & OUTPUTS

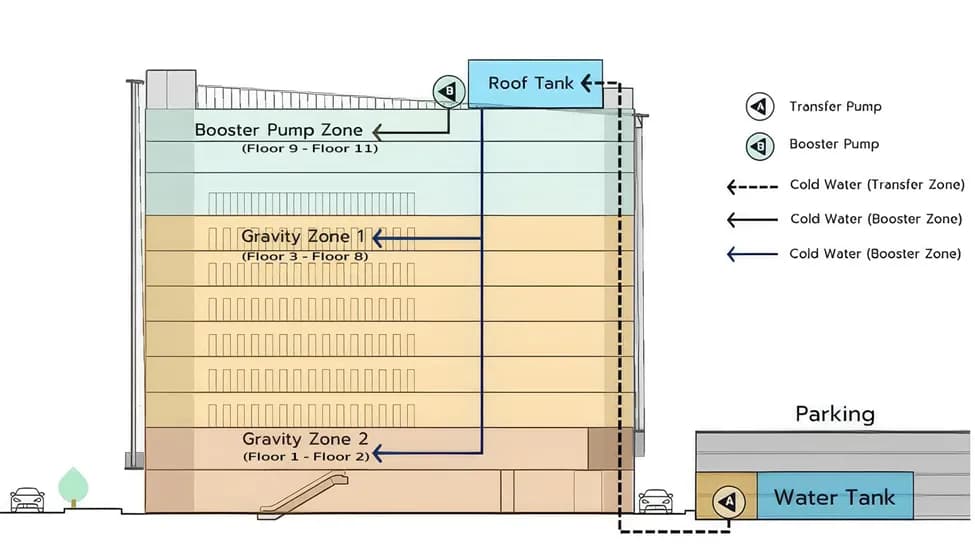

Down-Feed Water System Diagram

Schematic illustrating roof tank, gravity zones, booster pump zone, and transfer pump arrangement for reliable water distribution.

Need coordinated MEP design?

Start your project brief below — our MEP engineers will reach out to discuss your project needs.